// Quality

In-house quality facilities

-

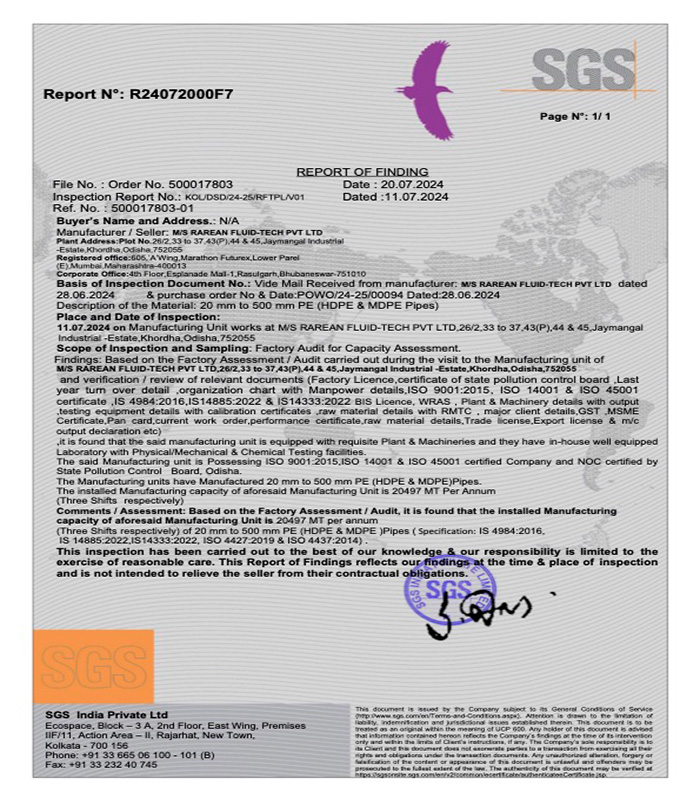

RAREAN is committed to manufacturing & supplying products as per customers’ requirements in time through continual improvement in the quality management system and professional workforce.

-

Our manufacturing unit has its own in-house Lab equipped with the latest equipment and manned by highly qualified & technical staff.

-

The company has a strict quality plan and stringent quality assurance system right from the raw material stage to the finished product stage.

*Our lab is soon going to be accredited by NABL -

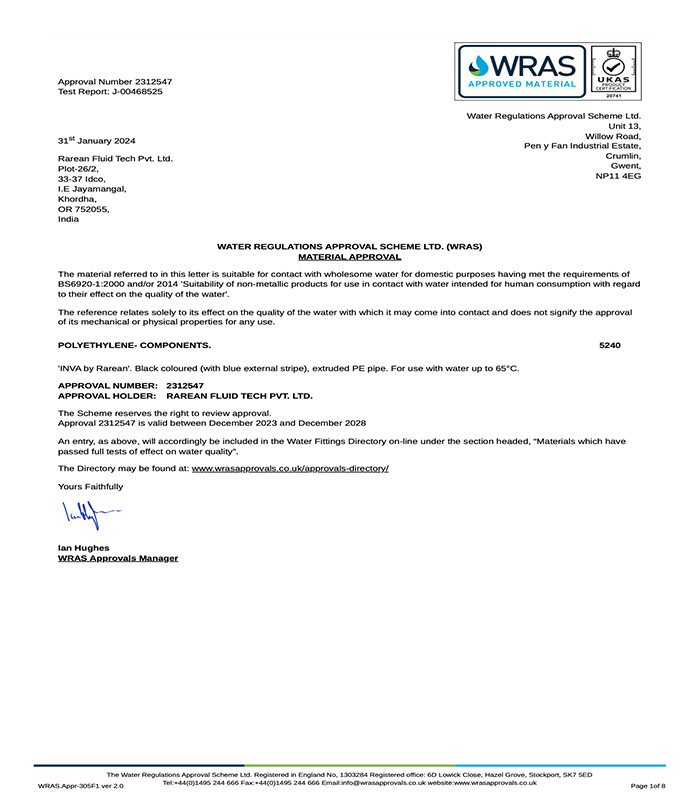

Certified by LRQA for Integrated Management Systems, and our pipes are WRAS-approved by NFS for potable water supply up to 65°C.

// Quality

Technological USP

-

Large processing window. Designed for high-output .

-

Swarfless cutting ensures pipes have clean, ready-to-joint ends.

-

Our QC Laboratory is fully equipped with all mandatory technology.

-

Internal pipe cooling system - reduction of sagging/ovality of the finished goods.

-

Automated raw material blending processes result in pipes with fewer defects.

-

All production lines are provided with Alternate Power supply systems like UPS.

-

The INOEX automatic gravimetric RM feeding system for high dimension accuracy.

-

Reduced Carbon Footprint.

// Quality

In-house testing facilities

Raw material testing -

-

Carbon Black Content & Dispersion Test

-

Density Test

-

Melt Flow Rate Test

-

Oxidation Induction Time Test (OIT)

-

Volatile Matter

-

Ash Content

-

Moisture Content

-

Pigment Dispersion

Pipe testing -

-

Dimension, length, colour, stripe & visual appearance test

-

Density

-

MFI

-

OIT

-

Yield strength

-

Elongation

-

CBC & CBD9

-

Reversion test

-

Pigment dispersion

-

Hydrostatic pressure

-

Notch pipe pressure test

-

Squeeze off test

-

Slow crack growth

-

Resistance to weathering

-

Overall migration